How the new QOCO Assignment can solve your current and future resource allocation challenges

The current state of aircraft maintenance planning

In a recent study on airline delays in the US it was stated that almost a quarter of flights were delayed. The most common root cause being the airline itself. As causes for these delays were several culprits which included, among others, staffing shortages and aircraft maintenance.

It is widely known in the industry that maintenance planning is currently handled in a stark contrast to the technology heavy ways in which other areas of the industry operate. And even if existing M&E systems do help with certain parts, they often lack the integrations and intelligence that makes planning easy and efficient.

But as if that is not enough, and adding insult to injury, many still use excel sheets and even pen and paper for their maintenance planning. Needless to say, this creates enormous resourcing inefficiencies.

Going paperless in aviation is not just a fad, but is becoming a business critical part. Many maintenance technologies already exist that will change the industry. One of them is MROTools.io, which enables digitalising tooling control in a safe and efficient way.

Interested in exploring how MRO software enables streamlined planning and scheduling in maintenance operations? Read our in-depth article on everything you need to know about MRO software to learn more.

Meanwhile, the industry is worrying about the upcoming resource shortages for technicians and engineers. According to a study by Oliver Wyman, Boeing estimated that over the next 20 years the industry will need 612,000 new pilots, 626,000 new maintenance technicians, and 886,000 new cabin crew members. Something is obviously not right at the moment. And while it seems some efforts are made to tackle the problem, the actual situation requires a proactive approach in order not to sit with the ace of spades when new requirements and systems are introduced.

How should we manage this? One of the answers is a rather obvious one, efficient resourcing of existing staff. The pen and paper approach is becoming unsustainable if MRO's are to keep up with the expected growth while tackling the shortages. This happens with smart, easy to implement software.

Fortunately one has just entered the market.

How QOCO Assignment addresses aircraft maintenance planning by AI and automation

Assignment was created to address industry needs and developed through actual on-site experience in the hangar and on the apron. In the last 10 years extensive work with several MRO’s and Airlines eventually lead to the development of the intelligent software.

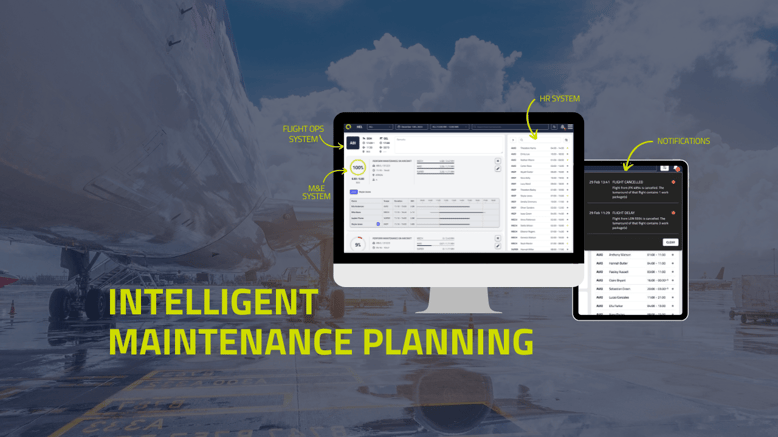

The first step was to seamlessly integrate the three main components of information used in maintenance planning, the Flight Ops System, the M&E system and the HR card.

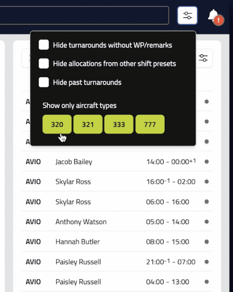

The visual interface combines the three systems in a simple system that allows granular visibility on all aspects of planning.

One of the standout features of the software is is its integration with flight operations and M&E systems. This integration provides real-time data on aircraft arrivals, gates, and subsequent departures, allowing planners to allocate manpower efficiently and respond to changes in flight schedules.

This isn’t just data; it’s actionable intelligence.

Moving from reactive to proactive maintenance planning

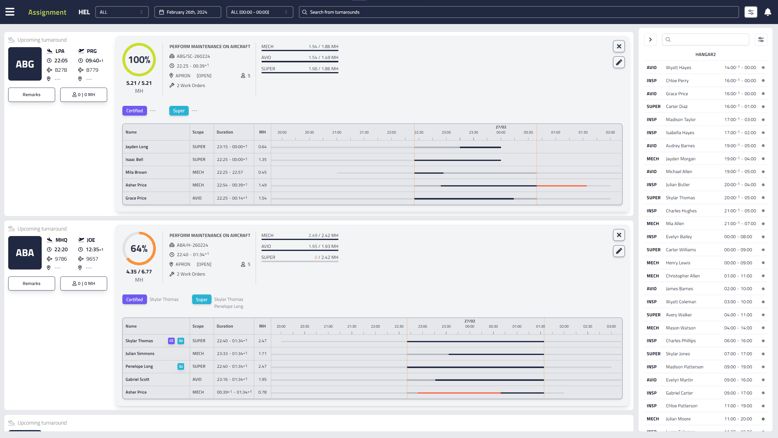

The application’s strength lies in its proactive planning capabilities. Planners are equipped with real-time updates on staff availability, shift patterns, and work order specifics, enabling them to make informed decisions swiftly. This proactive approach reduces downtime and improves response to unplanned events, like weather disruptions or technical issues.

Instead of reacting to the day’s challenges, it allows you to look ahead — 72 hours, 14 days, even months. It isn’t simply planning; it's forecasting, ensuring you’re always a step ahead.

How does Assignment handle delays?

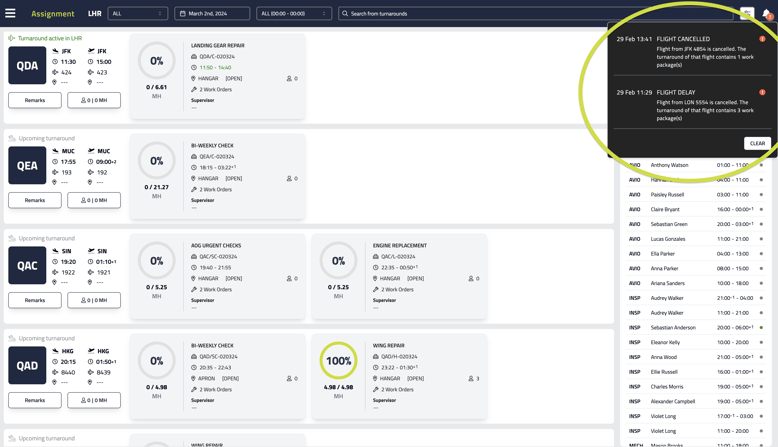

As mentioned earlier, delays are becoming increasingly common and cause ripple effects further down the maintenance planning. Several systems usually needs checking and then the updates take a massive amount of repetitive manual tasking that is done over and over again for every new delay.

Staff utilisation rates suffer, fleet availability decreases and costs increase. We know this causes headaches across all MRO’s.

As you can see, this is where Assignment thrives.Instead of costly and time consuming labour, the software allows incredibly smooth planning and fast reactions to overwhelming rapid changes.

But the application goes even further, notifying for not only delays but also diversions and cancellations, allowing you to be on top of your resources with at all times.

How does it handle multi-site maintenance planning?

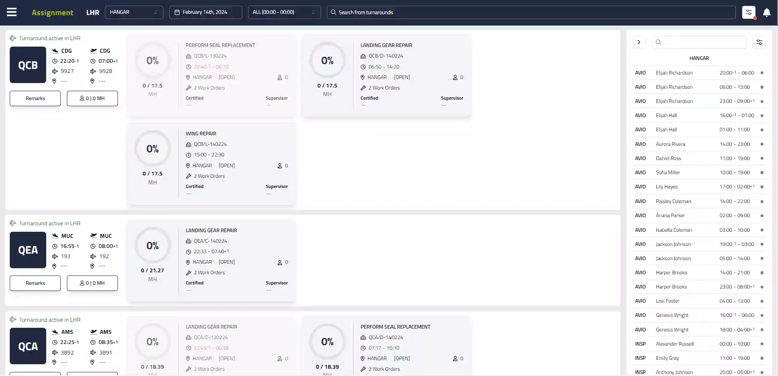

The beauty of the software is its flexible scheduling across global operations. It is built for both small and large operations, leaving no stone unturned and keeping maintenance planning easy while at the same time giving that granular overview of all important component. With its global perspective, Assignment caters to various airport locations, hangars, and aprons, providing unparalleled flexibility in scheduling. The interface allows easy switching between different sites, such as London Heathrow's multiple terminals, enhancing the planner's ability to manage staff across diverse locations seamlessly.

But once again Assignment delivers an even more detailed approach. A single tap opens up the possibility to single down the resources by aircraft type. In this example aircraft types are ready for filtering and afterwards the capabilities available are seen on the HR column on the right hand side.

How to customise MROTools.io – Assignment to your needs?

We understand every business is different and the challenges vary, that is why Assignment is fully customisable for your operations. And it’s as easy as everything else.

One of the main issues with resourcing is inefficiencies. With so many moving parts a lot of key assets on the ground are underutilised.

Optimizing staff ratios for maximum efficiency

One of the pivotal features of 'Assignment' is its ability to optimize staff ratios. The application ensures a balanced distribution of workload, considering the crucial balance between work and rest for engineers. Its sophisticated algorithms dynamically adjust staff allocation and shift configurations, guaranteeing that personnel are utilized effectively while adhering to safety and regulatory standards.

In the management panel you can easily change and add shifts, set roles, delay notifications and everything else you need to have that system working for you and not against you, all in beautiful intelligent automations.

Strategic Allocation of Work Packages

Assignment excels in allocating work packages intelligently.By setting thresholds for workload distribution, it ensures operational efficiency. The aim is always to maintain high productivity, with over 80% of work packages allocated optimally. Its about finding that delicate balance of work and rest for the engineering teams. It’s not just about filling shifts; it’s about calibrating workloads in a way that's humane and efficient.

This strategic approach prevents delays and bottlenecks, ensuring smooth operations in maintenance hangers. Once the settings have been adjusted and fixed for your specific needs, Assignment is ready to move you from planning to reviewing.

Harnessing AI for Operational Excellence

At the heart of Assignment is its sophisticated artificial intelligence. This AI-driven approach ensures optimal manpower allocation and operational efficiency. The system intelligently suggests staffing adjustments, reducing manual input and enhancing decision-making accuracy.

Strategic workforce management insights

Beyond day-to-day operations, Assignment offers strategic insights critical for workforce management. The application provides data that supports decisions on hiring needs, training requirements, and shift planning. This information is invaluable for justifying resource needs to upper management and ensuring the right mix of skills and personnel is available at all times.

Conclusion: Elevating aircraft maintenance planning to new heights

Assignment is not just a tool; it's a strategic partner in aircraft maintenance. Its combination of AI, real-time data integration, and flexible scheduling transforms how maintenance planning is conducted. By reducing manual workload and increasing operational efficiency, Assignment sets a new standard in the aviation industry, ensuring that maintenance teams are well-equipped, proactive, and ready to tackle the dynamic challenges of aircraft maintenance.

It introduces a personalized, intelligent approach in a sector often overwhelmed with generic methods. Assignment isn't merely about organizing maintenance tasks; it's about redefining how these tasks are approached, with a focus on efficiency, foresight, and a deep understanding of operational needs.

What are you waiting for? Book a demo and see the magic of Assignment yourself.

Tomi Kaukinen

Tomi Kaukinen

If you are interested in knowing how you can improve your efficiency in maintenance operations, book a 30-minutes discovery call with us.

If you are interested in knowing how you can improve your efficiency in maintenance operations, book a 30-minutes discovery call with us..png?width=600&name=63526beb32c2666a654e40fd_Untitled%20design%20(2).png)

.webp?width=600&name=6555d3f4aec7caa690ec12f3_IMG_5379%20(1).webp)